ELYSATOR – a Swiss pioneer in the water technology

The Swiss tradition company Elysator exists since 1950 and has committed itself from the very beginning of an ecological form of "water engineering". Already in the top management floor knowledge, unite in classical mechanics and fitter with those of electrical engineering. Before ecological thinking and sustainability were part of a widespread think Elysator turned his developments and technical equipment according to these maxims. At the latest with the breakthrough of ELYSATOR for heating systems the name Elysator is indispensable. Over the years, Elysator could up work with his visionary approaches in the field of water chemistry and heating technology to the absolute market leader in Switzerland. Meanwhile, the name is known far beyond the borders of the Alpine republic and the attitude of the company founders Rickenbach has not changed until today. With the launch of the Purotap Expert System based hyperfiltration, this was again clearly demonstrated in 2014.

Since 2013 Elysator from Bilten operates not only with advanced production equipment, innovative products, an unbroken logistics, consistent quality and excellent customer service, but also knows how to impress with training and technical advice.

The development of ELYSATOR:

- The 1970‘s – The development of the ELYSATOR® and founding of ELYSATOR AG in Zurich

- 1988 – Recognition of the ELYSATOR® as “state of the art”

- 1991 - Foundation of a subsidiary in Germany

- 2004 - Development and registration of PUROTAP ®

- 2010 – Spin-off of the largest water laboratory for the SHK industry

- 2011 – move in new premises and stockrooms in Abstatt (Germany)

- 2013 - New building of the head office in Bilten (Switzerland)

- 2013 - Development and patenting of SorbOx ®

- 2014 - Development PUROTAP ® expert, full desalination by hyperfiltration

The Elysator family

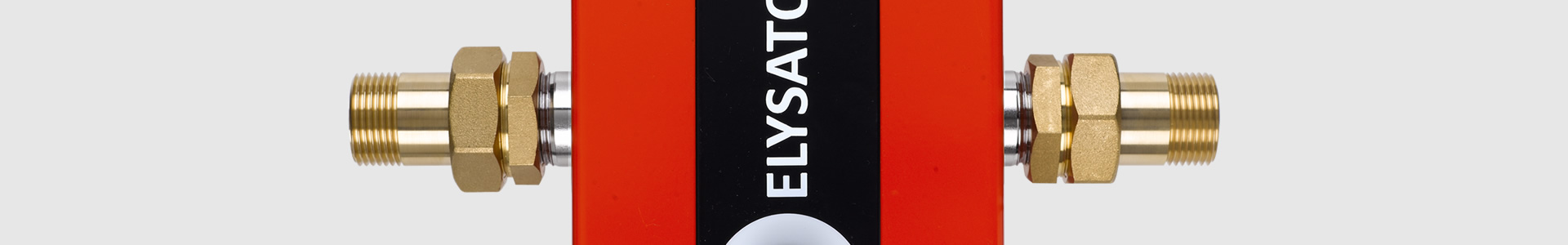

With over 30 years of experience and the most environmentally friendly and most sustainable operating system on the market for filter systems for heating systems Elysator provides the Elysator and Elysator trio not only for operators of large heating systems, but also for wise individuals with economy activity the optimal solution. Both systems are designed for the most different large heating systems and can be easily integrated into existing systems. Both the Elysator and the Elysator trio are extremely low maintenance and do not require am external power supply. In the normal case you will need service every three to six years with the Elysator whereas you needed a service once a year where you had to spend lot of money and time without the Elysator.

Both series come completely without the use of chemicals and are recommended by leading professional associations, institutions and producers.

The Purotap family

All Purotap solutions are based on the latest requirements and quality standards. Including the Association of German Engineers (VDI) standard norm 2035, which states: “With decreasing water salinity increasing amounts of oxygen can be tolerated. In the absence of ions that can take over the transport of electric current in the water, is the formation of galvanic cells, which may lead to localized corrosion, virtually impossible. (…) For initial filling larger water heating installations using demineralized water is recommended.” However, the DIN 50930 of the German Institute for Standardization e. V. (DIN) paid full attention in developing the Purotap systems. According to this chloride and sulfate ions stimulate the anodic partial reaction of metal dissolution. By selective anion exchange the probability of local corrosion can be reduced.

Another fulfilled standard are the provisions of the Swiss Association of Heating and Air engineers (SKWI). The Swiss standard requires: “The filling and make-up water must be desalinated.” On top of that are the SKWI states that "the best technical solution is demineralization in waters with high chloride or sulfate content".

SANOL H-15 and SANOMAT 20

Each water system (heating, solar or cooling system) needs to be cleaned prior to final filling with treated water. This is especially true for older and refurbished systems. In this process, foreign materials (eg drawing greases, corrosion residue, solder, flux and welding agent) are removed from the system. However, even by a physical purging according to DIN 1988 (rinsing with speed, surge irrigation, reverse circulation, rinse with solid bodies) do not remove completely. Only the use of suitable cleaning agents (often based on fruit acids) reaches a residue-free removal of these substances.

The DIN EN 14336, still unheard by many professionals, provides that water systems must be rinsed. Unfortunately, the standard does not describe how that should be done. Most rinses are pointless, wasted time and even counterproductive, because the correct nominal width and arrangements of the rinse support a professional rinse is not permitted.

Plus, the cleaning agent must be removed completely, otherwise it can cause devastating effects to the treated filling water.

The market leader Elysator developed the flushing device SANOMAT 20 specifically for flushing of heating systems. Selective deflection of the flow directions of the existing heating water also allows the removal of the most stubborn accumulations and blockages in the heating system. Through a growing primary pressure of the rinse water, a simple folding of this controller can reverse the complete flushing direction. The flushing action is repeatedly amplified by the addition of compressed air.

With SANOL H-15, the cleaning work is safer and cheaper. SANOL H-15 is a novel, highly effective cleaning agent from the market leader Elysator. It surrounds the particles of loose and easily adhering sludges. Thus they become more buoyant and can be flushed very easily. SANOL H-15 has to act a few days to develop to the maximum effect.

Unlike conventional detergents, SANOL H-15 is suitable for any system water quality and is completely safe for all system components.

Puroclean

In ELYSATOR Puroclean system, an inexpensive type of demineralization is used. This technique has Elysator, gained as market leader in demineralization in heating systems, from its long experience in this field. In the case of the Puroclean system the basic technique of proven Purotap cartridges and Purotap systems was transferred on a high-quality and portable cleaning device.

The problem formulation in the background

In the past, the majority of underfloor heating were installed with plastic tubes, which are not impermeable to oxygen. Meanwhile, it is fortunately easily possible to produce heating pipes for floor heating systems and to obstruct the diffusion function on nearly tight. Indeed, the best heating system also disposes of enough elements, which cannot call this quality their own. This is valid not only for valves, screw connections, circulating pumps, but also for control units, automatic breathers and defective expansion vessels. At these places, it also comes in very modern heating systems to an unintentional oxygen admission. This oxygen, a too deep pH factor, but also a raised conductivity of the filling water are typical triggers for damages of heating installations.

To guarantee a long life span for modern heating systems, all manufacturers give comprehensive tips and directives. These suggest demineralizing the filling water for every heating system. A reason for it are experiences from the practice, which underpin that already minimum steps of hardness in the filling water lead to damages in high-quality devices like gas-fired hot-water tank, warm pumps and solar arrangements. One of the most frequent causes is the amount of lime in the filling water. Using the example of a detached house with a heating system of 350 liters system water content results in average amount of 100g lime in the filling. Although this amount may seem small, it is able to damage by lime precipitation the built heating system permanently. The amount of lime increases, of course, with the amount of the used filling water. In addition, it varies from region to region due to the different degrees of hardness of the tap water.

Counteract corrosion from the beginning

Also damaging for sensitive devices such as heating baths is the penetration of the filling water with salts. Therefore, it comes to corrosion of the lines within the heating system. Electrochemical reactions have a harmful effect on the metallic parts of the system and accelerate the wear process. Benefiting from a high amount of salts the formation of galvanic elements is promoted that ultimately cause this corrosion. It also contained in the unfiltered water, chlorides, sulphates and nitrates have their not insignificant proportion.

It is true that, at simple softened water, calcium and magnesium ions exchanged for sodium ions, thus removed from the water hardness, and significantly lowered the hardness grades, but the salinity of the water remains unchanged. In case of modern systems, an important damage factor remains completely unchanged.

Earlier it was especially set for inhibiting corrosion on chemical types of corrosion protection. In many cases, however, it was found that especially in hard to reach places on glands, but also in already by rust and dirt damaged places no more active protective effect could be obtained and the real problems were solved so only dissatisfactory. Made even more difficult to perform such protection method proves the need for constant monitoring. This is not only time-consuming but also costly. The attempt to split the heating system into two parts (heating circuit and kettle circle) by using heating exchangers, only leads to two separate problem areas in the long run, but not to sustainable solution to the problem. In addition, modern heating systems are significantly more prone to silting, blockage of control valves and pumps and precipitation by lime and other water constituents. The consequences range from quick corrosion breakthroughs in the boiler, flow noises by gas developments, increased energy consumption to serious water damage.

The solution

ELYSATOR complete product range is aimed at the professional craftsmen and maintenance service but also to the homeowner alike. All solutions serve to protect your possessions and your money. Damages to heating systems are always expensive, but can be avoided from the beginning.