Counteract the corrosion

Also in the filling damaging located salts act on such a modern heating systems. In closed heating systems can occur indeed actually no corrosion, but the practice shows that it happens anyway. The reason for this are electrochemical reactions in the tap water. Benefiting from a high amount of salts the formation of galvanic elements is promoted that ultimately cause this corrosion. But also in the unfiltered water containing chlorides, sulfates and nitrates have their share of such decay processes.

It is true that, at simple softened water, calcium and magnesium ions exchanged for sodium ions, thus removed from the water hardness, and significantly lowered the hardness grades, but the salinity of the water remains unchanged. In case of modern systems, an important damage factor remains completely unchanged.

Solution besides from the known method with resin consumption. The costs compared to other ion exchangers are more than ten times lower.

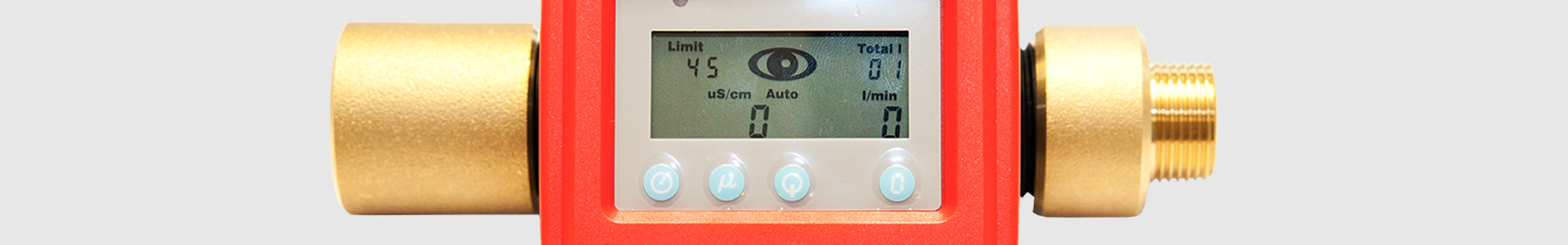

The Purotap expert is especially for large plants and long-distance heating systems and offers the maintenance service not only a portable solution to demineralize the water, but also captivates more by its user-friendliness and good workmanship. Equipped with a precise measuring computer, it is simple, to obtain accurate information about the status of water, the salt content and the degree of hardness. On request, it shall indicate the mineral content or the conductivity of the water and warns the user if the capacity of the cartridge is exhausted. The integrated flow meter displays the output per liter and ascertained the already treated water quantity in the heating system. The power supply takes place entirely using conventional batteries. It is equipped with wheels for better transport.

The lance of Purotap expert system is made of long-lasting stainless steel and chrome steel. The filling speed is maximum 1,200 liters per hour at a maximum production capacity of 100,000 liters.

Purotap Expert is based on hyperfiltration - a process of the latest generation. Using computer simulation, the flow paths of water were drawn in elaborately constructed container that an incomparably high filtration rate can be achieved.

With the integrated high-pressure pump, Purotap Expert reaches a production capacity of 20 l / min, or 1200 liters per hour. The raw water is pressed with Purotap Expert up to 18 bar through a filter membrane having a pore size of less than one nanometer - this is one millionth of one millimeter. All dissolved minerals and salts are retained there, and only the pure water molecules pass through the membrane. The hyper filtered water is particularly well suited for industrial applications, since in addition to the dissolved minerals, heavy metals and pesticides, bacteria and organic materials are removed from the water.

Thanks to an optimized and fully automated rinsing, the filter membrane is cleaned continuously during operation. All components of Purotap Expert are mechanically and normally functioning. Failure-prone controllers and control valves could be dispensed thanks to constructional innovation.

Data sheet Purotap Expert

- max. operating temperature in °C = 60

- max. flow l/hrs. 1 200 l with 1-9 bar

- Connection size in duty 1" AG

- Weight 100 kg

- Mobile filling station with flow and amount counter.

- Electronic measurement of the relaxed materials in the Raw and treated water by measuring computer.

- Incl. pressure reduction, Cutting and stop valves. Chrome steel tank on roll neck mounts.

The advantages of the mobile Purotap expert filling station are obvious

With the Purotap Easy system for refilling heating water according to VDI 2035 Elysator fills a real gap in service. In contrast to the usual demineralization cartridges, the complete demineralization can be controlled through a specially designed and battery-powered measuring counter. The high-quality filling cartridge is made of chrome steel, sturdy and suitable for everyday use in the craft shop and at the customer site. Despite the high power capacity and a total output of 100,000 liters, the whole system does not weigh more than 100 kg.

The Purotap expert system made possible by its ease of use and the optimum overview during the softening and demineralization. With the space-saving designed filling station on wheels remains on the service vehicle space for other important tools.

The demineralized water by hyper filtration is ideal for cleaning work on windows, solar panels and vehicle fleets.

The mobile filling station Purotap expert fulfil latest requirements and quality standards. Including the Association of German Engineers (VDI) standard norm 2035, which states: “With decreasing water salinity increasing amounts of oxygen can be tolerated. In the absence of ions that can take over the transport of electric current in the water, is the formation of galvanic cells, which may lead to localized corrosion, virtually impossible. (…) For initial filling larger water heating installations using demineralized water is recommended.” However, the DIN 50930 of the German Institute for Standardization e. V. (DIN) paid full attention in developing the Purotap systems. According to this chloride and sulfate ions stimulate the anodic partial reaction of metal dissolution. By selective anion exchange the probability of local corrosion can be reduced.

Another fulfilled standard are the provisions of the Swiss Association of Heating and Air engineers (SKWI). The Swiss standard requires: "The filling and make-up water must be desalinated." On top of that are the SKWI states that "the best technical solution is demineralization in waters with high chloride or sulfate content".

Likewise, the öNORM 5195-1 is fully respected. "When filling water filtered (pore size not greater than 25 μm) water should be used (...).Depending on the overall performance of the heat generator following approximate values of total hardness should not be exceeded:

- to 150 kW 17 °dH

- more than 150 kW to 1000 kW 3 °dH

- more than 1000 kW 0,5 °dH.

If significant parts of the plant or the entire plant are repeatedly filled, so in plants with a total capacity up to 150 kW is the filling water to soften at 3° dH. If these values can not be complied with, appropriate water softeners (eg ion exchangers) are provided."